Introduction to Plastic Printers

Selecting an optimal plastic printer is a decision of paramount importance for manufacturing businesses. This guide aims to distill the essence of the intricate selection process, empowering informed decision-making.

Exploring Various Plastic Printer Models

Identifying which model suits your requirements hinges on understanding the spectrum of available plastic printers, each tailored to specific production scales and applications.

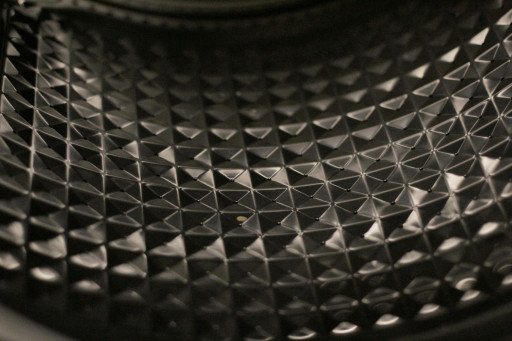

3D Plastic Printing Innovations

The transformative 3D plastic printing technology enables crafting complex shapes with additive manufacturing techniques, offering customization opportunities previously unattainable.

Injection Moulding Precision

Moulding machines shine in mass-producing identical parts, delivering speed and consistent output for high-volume demands.

Innovative Blow Molding for Hollow Parts

To create hollow items such as containers, blow molding stands out, utilizing air pressure to mold plastics into shapes within a mold.

Extrusion Printers and Continuous Shapes

For continuous products like pipes, extrusion printers push molten plastics through dies, achieving uniform cross-sections consistently.

Key Considerations for Plastic Printer Acquisition

Investing in a plastic printer warrants a nuanced approach, encompassing several pivotal factors to align with your operational needs.

Assessing Production Volume Needs

The scale of your production influences your machine choice, with high-volume facilities favoring robust, continuous-operation models, and low-volume setups opting for flexibility.

Print Speed: A Metric of Efficiency

Faster cycle times amplify production, yet precision must remain sacrosanct to uphold product standards.

Adaptable Machinery for Diverse Products

The array of products you plan to fabricate should reflect on the versatility of the printer, enabling diverse outputs without extensive modifications.

Compatibility with Plastics

Your chosen machine must accommodate the specific types of plastics needed for your products to maintain seamless operations.

Longevity and Easy Maintenance

Opt for durable, easily maintained printers to minimize disruptions and maintenance expenses.

Calculating Cost-Effectiveness

A cost-effective plastic printer balances initial expenditures against long-term operational savings, considering maintenance, materials, and energy efficiency.

Embracing Technological Advancements in Plastic Printing

Remaining current with technological progress can distinguish your business in a competitive landscape, integrating the latest innovations for enhanced capabilities.

Automation and Robotics Integration

Modern printers increasingly use automation and robotics to heighten precision, reduce labor costs, and bolster safety, streamlining production.

Capacities of Smart Technology

Smart features in printers allow for operation optimization via real-time monitoring and predictive maintenance.

Eco-Conscious Printing Practices

Aligning with sustainability trends, many printers now support energy-efficient operations and the use of eco-friendly materials.

Customization for Unique Requirements

Manufacturers might offer tailored plastic printers, catering to individualized production specifications, from machine dimensions to bespoke technological solutions.

Navigating the Plastic Printer Market

The search for the right plastic printer may seem overwhelming; discerning the suitable option requires strategic investigation.

Extensive Market Analysis

Begin by exploring the landscape of plastic printer suppliers, examining their reputations and customer feedback.

Learn more about plastic printing technologies.

Detailed Technical Assessments

Scrutinize each printer’s technical details, benchmarking features and performances while contemplating comprehensive support services.

Professional Guidance for Decision-Making

When uncertainty looms, consulting experts can illuminate the path to the most appropriate printer that reconciles with your objectives.

Witnessing Demonstrations

Acknowledge the necessity of live demonstrations or sample prints to evaluate a printer’s competencies and align them with your quality benchmarks.

The Importance of After-Sale Support

Warranties, spare parts availability, and technical support are critical in post-purchase scenarios; hence, they must factor into your decision calculus.

Optimizing ROI Post-Purchase

Securing a plastic printer prompts strategizing for maximal return on investment, enhancing profitability through operational excellence.

Training for Peak Performance

Comprehensive training fosters staff proficiency in both utilization and upkeep, diminishing error rates while bolstering productivity.

Tracking Performance Indicators

Constant monitoring of performance parameters unveils optimization opportunities that can refine processes and minimize wastage.

Routine Maintenance Imperative

Maintaining consistent machine upkeep schedules extends operational life and sustains high-caliber performance.

Staying Current with Sector Dynamics

Adaptability to industry evolutions can secure an advantageous position, maximizing the utility of your plastic printing assets.

Periodic Product Line Reviews

Analyze and adjust your product offerings in accordance with market demands, ensuring your production strategies remain relevant.

Conclusive Thoughts

Deciding on the ultimate plastic printer for your manufacturing imperatives is a complex task. It entails a comprehensive understanding of machine types, technological trends, and an unwavering commitment to optimizing ROI. By navigating these facets wisely, businesses can select a solution that not only fulfills but surpasses their production aspirations.

Explore the steps for industrial cutting machine selection guide.

Related Posts

- 5 Top Industrial Rope Selection Strategies for Optimized Use

- Advancements in Weaving Farm Machinery: 7 Key Developments Shaping Agriculture

- The Comprehensive 5-Step Guide: Metal Machine Shop Technology and Expertise in the Modern World

- Steel Machining Excellence: 7 Proven Strategies for Industry Leaders

- 5 Tips for Precision Machine Shop Selection in Your Area